| Short-path distillation / molecular distillation |

| | Fundamental | A short path distillation under high vacuum (<10Pa) conditions, the heating surface is evaporated through the shortest possible distance molecules reach the condensation surface for the condensation, in order to achieve liquid - liquid separation process by distillation. When the distance between the heating surface and the condensation surface is less than or equal to the mean free path of the operating elements is evaporated under vacuum and the temperature of the distillation process is also called molecular distillation. It has a low temperature distillation, vacuum distillation of high, short heating time, the degree of separation advantages, is a relatively new yet widely used in industrial production separation technology. Material from the flange into the short distillation head, through the distribution of the material on the disc of the rotor continuously and uniformly distributed to the heating surface perpendicular to the cylinder, the material falling by gravity while the scraping device is rotated to force the film formed on the heating surface thin film-like turbulence. After evaporation of the molecule is a short distance to the condenser and condensed built through the bottom of the evaporator of the discharge port, the heavies short distillation residue into the collection tank and discharged from the outlet side. Built-in distance to the condenser and condensed down through the bottom of the discharge port of the evaporator is discharged into the parts of the recombinant short distillation residue collection tank and discharged from the outlet side. Distillation of the following steps: Distillation of the following steps: the distance to the condenser and condensed built through the material discharge port at the bottom of the evaporator, the residue was collected into the groove parts of the recombinant short path distillation unit and discharged from the outlet side. Distillation of the following steps: Distance material in the film formed on the surface of the heating condenser and the condensate reaches built down through the bottom of the evaporator unit of the discharge port, the residue was collected into the groove parts of the recombinant short distillation and discharged from the outlet side. Distillation of the following steps: Molecules on the surface of film evaporation and condensation from the condenser built reaches down through the bottom of the discharge port of the evaporator is discharged into the parts of the recombinant short distillation residue collection tank and discharged from the outlet side. Distillation of the following steps:

Is heated for evaporation of the condensation from the surface of the molecular movement of the distance to the condenser and condensed built down through the bottom of the discharge port of the evaporator is discharged into the parts of the recombinant short distillation residue collection tank and discharged from the outlet side.

Distillation of the following steps:

Condensing the evaporated molecules condensing surface

Collecting emissions and residues of the distillation | | | | Features | ◆ high vacuum, low temperature distillation: Working vacuum: 0.1Pa ~ 10 Pa; ◆ heat transfer coefficient, high evaporation efficiency: means for rotating the film in scraping the inner surface of the evaporation tube material into a uniform film scraping effectively reducing the thermal resistance at a high degree of vacuum, so that the material is very easy to evaporate easily from the material separated by distillation; film because the film scraping the surface of the cylinder body between the intense turbulence in the state of the different components of the material transfer and heat transfer jacket with the heating medium heating folders are very efficient; addition due to the high quality finish and scratch the film's non-stop movement of the inner surface of the cylinder, making the heating surface is not easy to coking, scaling, but also help to increase the overall heat transfer coefficient and improve the evaporation efficiency. ◆ heating time is short: the material into short distiller evenly distributed by the distribution plate is heated to a vertical surface under the effect of gravity and double wiper along the transfer film under heating-section helical limited length, stay within the evaporator Time is very short, usually several seconds to tens of seconds (average residence time and the length of the heating surface, scraping the film's characteristic form and material thickness and other parameters related). In addition, DZ series short distiller "no dead ends," designed to avoid the distribution of the material in the disk, the heating surface and scrape the accumulation of membrane systems and other parts, reducing the thermal polymerization heat-sensitive materials and thermal decomposition. | | | | Structural features |  ◆ High-precision transmission and mechanical seals designed to ensure long-term stable operation ◆ High-precision transmission and mechanical seals designed to ensure long-term stable operation

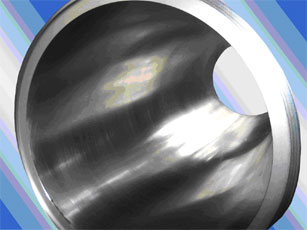

DZ series of short distiller's transmission and precision mechanical seal is designed to meet the long-term stable operation of equipment specifically designed and manufactured, and to determine the reduction ratio transmission device according to the conditions and material properties of short distiller, mechanical seal lubrication mode (forced circulation lubrication, stationary lubrication) and mechanical seal cooling. ◆ evaporation cylinder whole molding process, without intermediate flange connection Short-path distillation of the evaporator tube from the inner cylinder and the heating jacket composed of a short distiller's core components. DZ series of short distiller cylinder are integral molding process, evaporation tube without intermediate flange connection. Overall molding cylinder flange connection not only to avoid the leakage and materials brought accumulates, and avoid hypothermia occurs on both sides of the flange area, leading to the evaporation surface is not effectively utilized. In addition, the overall molding cylinder can be most effectively ensure the accuracy and good film-forming effect of the device. ◆ tube internal surface finish, easy to stick material  As the inner surface of the cylinder is heated evaporation surface short distiller, the surface finish is a strict requirement, DZ series of short distiller's body after the rough surface of the cylinder reaches the set size requirements, so that by the grinding surface finish to Ra0 .8 μm, can be difficult to stick to ensure that the inner surface of the material and scale, reduce material retention, improve the efficiency of heat and mass transfer. According to the special requirements of the food and pharmaceutical industries, but also a special polishing technique can be used to achieve surface finish Ra0.2μm. As the inner surface of the cylinder is heated evaporation surface short distiller, the surface finish is a strict requirement, DZ series of short distiller's body after the rough surface of the cylinder reaches the set size requirements, so that by the grinding surface finish to Ra0 .8 μm, can be difficult to stick to ensure that the inner surface of the material and scale, reduce material retention, improve the efficiency of heat and mass transfer. According to the special requirements of the food and pharmaceutical industries, but also a special polishing technique can be used to achieve surface finish Ra0.2μm.

◆ unique liquid distributor and splash device is designed to effectively guarantee product quality

To improve the efficiency of evaporation, distillation short continuous and uniform distribution of the material perpendicular to the surface of the heating cylinder. DZ series of short-range liquid dispenser distiller's not only a uniform distribution of the materials to the heating surface, a small amount of the material can effectively prevent prolonged retention in the distributor, for high viscosity materials as well.

DZ series of short distiller precision design and manufacturing, to ensure long-term stable operation of scraping membrane device, its excellent film-forming properties of materials make the evaporation process becomes very soft, almost no spatter and entrainment, in most cases, Even without splash device can meet product requirements. When dealing with some special materials and when the products have special requirements, DZ series of short distiller splash device can be more reliable guarantee of product quality。

Scraping film form ◆ scraping film is in the form of a variety of optional use of a wide range: Oblique groove scraper blocks, drum; PTFE material using special temperature up to 280 ℃ Hinged metal scraper so fixed; | | | | Applications | Can replace conventional falling film evaporator, petrochemical and chemical products for distillation, purification, concentration, bleaching use; Especially for heat-sensitive, easily oxidized chemical industrial distillation refining; Distillation can be used for the separation of high-boiling products; Typical applications: Polyunsaturated fatty acids (oleic acid, linoleic acid, fish oil fatty acid (ester)) was purified by distillation and its derivatives; Monoglyceride refined; Refined dimer acid; VE, phytosterols refined; Distilling the liquid crystal; Polymer demonomerized; Other heat-sensitive products, purified; | | | | Product Selection | According to theoretical calculations and promote the application of short-path distillation of years of experience, Processing capacity and raw materials (products) short molecular distillation, material viscosity, operating conditions, the effective heat transfer area of the evaporator has a direct relationship.

Common feed rate: 100 kg / (m² h)

(Maximum 80 - 150 kg / (m² h)

Minimum Specifications: DZ-5 effective evaporation area 0.05 square

Maximum size: DZ-3600 effective evaporation area of 36 square feet.

Equipment Material: SUS304, SUS316L, SAF2205, and Hastelloy;

Operating temperature: up to 350 ℃

|

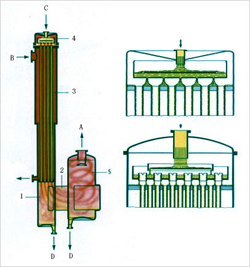

L film evaporator Climbing film evaporator, also known as l-film evaporator, it is based on the principle of siphon pump operation, according to the generated steam bubbles in the boiling process of the lift, and the flow of the liquid and vapor flow, while the amount of steam produced increases, whereby the the flow of the film produced on the wall, that is liquid up "to climb." And the flow of the movement has generated a high degree of turbulence in the ribs in the liquid. This evaporator is characterized by a long heating tube (about 5 ~ 7M), but the temperature of the heating chamber and the difference between the boiling chamber must be large, otherwise, the energy of the steam flow is insufficient to climb the liquid and the film transport . A: Imported Materials B: condensate outlet C: steam inlet D: concentrate exports E: secondary steam outlet | | | | | | | | | | | Falling film evaporator

In a falling film evaporator, liquid and vapor streams and downwardly flowing liquid to be concentrated is preheated to boiling temperature, the liquid distribution device by means of a uniform film on top of the evaporator into the heating pipe, flows downward at boiling temperature and partially evaporated down movement due to the introduction of gravity and flow of the steam flow continuously strengthened. In a falling film evaporator, the liquid is heated sufficiently wetted face of trouble-free operation of the device is extremely important. If the heating surface is not sufficiently wet, dry wall will occur locally and crusts, the worst case is heating tubes are completely blocked. In critical situations, wetting rate increases with the number of evaporator efficiency or division increases, therefore, should maintain the advantages of one-way operation. In this mode of operation, the contact time of the liquid and the heating surface is almost constant, each way is typically In addition to the pipe size, choose a suitable liquid distribution device is very important to get completely wet, the next move is the legend of two liquid distribution devices. Due to the low amount of liquid in the heating tube and the flow speed, the product residence time is quite short, so you can gently evaporate extremely heat-sensitive materials. |  |

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.